Precision Engineered for Coronary Intervention

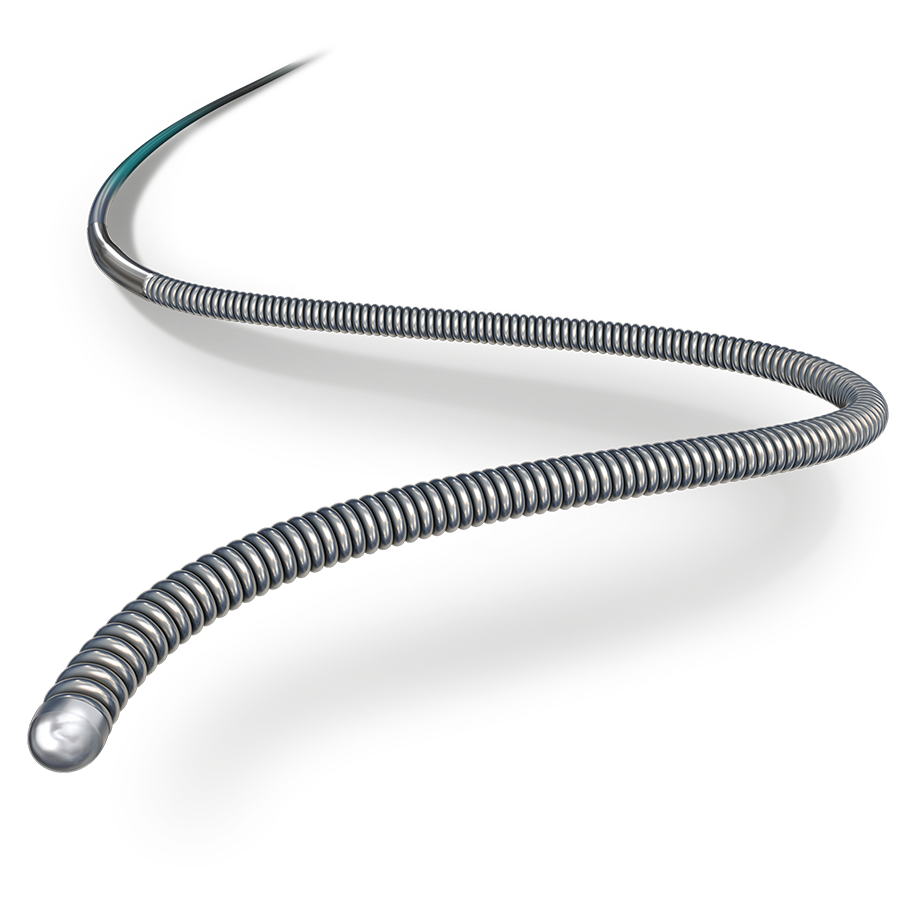

Successful Percutaneous Transluminal Coronary Angioplasty (PTCA) relies fundamentally on precise guidewire performance. Vasmed comprehensive portfolio of 0.014″ PTCA guidewires is engineered to meet the diverse challenges encountered in modern interventional cardiology, from navigating tortuous vessels to crossing complex lesions, including Chronic Total Occlusions (CTOs). Each wire from Vasmed is designed with specific material compositions and construction techniques to optimize critical performance characteristics.

Our guidewire designs incorporate advanced materials and manufacturing processes to achieve superior control and reliability:

Key Performance Characteristics for selecting the optimal guidewire

Vasmed guidewires are provided with varying tip load to support various interventional requirements, the tip-load is defined as gram force required to cause buckling or significant deflection of the distal wire tip. It quantifies the tip’s stiffness and penetration capability (higher load) versus its softness and potential for atraumatic navigation (lower load).

-

Vasmed Floppy Wire

< 0.7gmf

-

Vasmed Regular Wire

Between 0.8 – 0.9gmf

-

Vasmed Support/Extra Support Wire

Between 0.8 – 1.1gmf

Vasmed corewires are designed with advanced annealing processes that improve the support, torque and pushability. Pushability defined as the efficiency of transmitting axial force applied at the proximal end to the distal tip, enabling advancement through resistance without energy loss or shaft buckling. Primarily determined by core material stiffness and shaft construction.

Vasmed guidewire trackability allows the distal section to follow the natural course of the vessel, including tortuous segments, without prolapsing or deviating. Influenced by distal flexibility, tip design, and shaft coatings. The varying designs of tapers for the guidewire allows for more support at the distal section to highly flexible distal section, which allows usage with highly torturous vessels.

Vasmed guidewire crossability provides the capacity of the guidewire tip and distal segment to successfully navigate through tight stenotic lesions or complex obstructions. A function of tip profile, lubricity, tip load, and pushability providing sufficient forward force.

Vasmed guidewires are provided with 3 designs to support crossability

-

Coil Reinforced tip

-

Support reinforced tip

-

Urethane coated tip

In addition, all our wires use Silicon – hydrophobic coated which allows for optimal cross ability.

Ease of steerability is a key aspect for Vasmed guidewires, the fidelity of transmitting rotational force from the proximal manipulator to the distal tip at 1:1 ratio is Critical for precise directional control and navigating vessel bifurcations or angles.

The ability of the formed tip shape to resist deformation during navigation and device passage, crucial for maintaining steering control and preventing vessel trauma. Our tips are made in such a way that it easily resist deformation at the same time allow for user reshape of the tip.

Our Range of Guidewires

Our 0.014″ guidewire portfolio is categorized by primary function to facilitate selection based on procedural requirements

-

1Stainelss Steel Guidewires

-

2Nitinol Guidewires

-

3CTO Wires

Vasmed provides two core designs for optimal performance and selection

-

Stainless Steel Core Wires

Offer inherently high tensile strength, providing excellent pushability, support, and tactile feedback. Ideal for situations demanding robust shaft performance and device support.

-

Nitinol Core / Component Wires

Leverage the unique super-elastic and shape memory properties of Nitinol. Provide exceptional flexibility, kink resistance, and tip shape retention, particularly beneficial for navigating tortuous anatomy and maintaining tip shape integrity.

Vasmed Floppy wires can be used for Initial vessel access, navigating non-complex anatomy, procedures where minimizing vessel trauma is paramount.

-

Tip Load

Ultra-low (<0.7 g) for maximum safety and atraumatic passage.

-

Trackability

High degree of distal flexibility allows effortless navigation in relatively straightforward anatomy.

-

Tip Design

Soft, often shapeable tip (e.g., J-curve) designed to prolapse safely if resistance is met.

Nitinol distal core for superior flexibility, kink resistance, and shape retention. May feature extensive hydrophilic coating for enhanced trackability.

Vasmed Regular wires can be used for a broad spectrum of coronary lesions and anatomies encountered in routine interventions. Designed for versatile, reliable performance.

-

Tip Load

Moderate (typically 0.8 – 0.9 g), providing a balance between safety and lesion crossing capability.

-

Pushability & Support

Good axial force transmission for device delivery in common scenarios.

-

Trackability & Torque

Reliable performance in moderately tortuous vessels with responsive steering.

-

Tactile Feedback

Offers perceptible feedback to the operator.

Both Nitinol (LE) and multiple stainless-steel designs available as regular wires

Vasmed Support/Extra support wires can be used for cases requiring significant backup support for delivering bulky devices (stents, balloons), crossing calcified lesions, or anchoring techniques.

-

Pushability

Maximized through stiffer shaft construction for superior axial force transmission.

-

Support

Provides a stable rail, minimizing catheter prolapse during device advancement.

-

Tip Load

Moderate to high, offering sufficient support without overly compromising safety.

-

Torque Response

Generally good, though distal flexibility might be slightly reduced compared to workhorse wires.

Primary Use: Specifically designed to penetrate and traverse challenging Chronic Total Occlusions.

-

Tip Load

Graduated range, with moderate tip load 3-6gmf, allowing selection based on lesion morphology and crossing strategy.

-

Pushability

Exceptional axial force transmission is critical to deliver the necessary penetration force without buckling.

-

Crossability

Often feature specialized tip designs (tapered, hardened, non-tapered penetrating) and durable, lubricious coatings to facilitate entry and passage through resistant tissue.

-

Torque Control

High-fidelity torque response enables precise directional control within the occlusion

Specifications & Ordering Information

| Part No. | Wire Dia. | Wire Length | Tip Profile | Tip Length | Support Type | |

|---|---|---|---|---|---|---|

| 1 | 60000008 | 0.014″ | 1850 | Straight | 30mm | Floppy |

| 2 | 60000009 | 0.014″ | 1850 | J | 30mm | Floppy |

| 3 | 60000010 | 0.014″ | 1850 | Straight | 30mm | Normal |

| 4 | 60000011 | 0.014″ | 1850 | J | 30mm | Normal |

| 5 | 60000012 | 0.14″ | 1850 | Straight | 30mm | Extra Support |

| 6 | 60000013 | 0.014″ | 1850 | J | 30mm | Extra Support |